Adaptive Autonomy

No Programming Required

Let your team

focus on their craft.

Augmenting manual operations with robotic precision and an intuitive interface that can be quickly mastered.

Designed with

flexibility in mind.

From small to large scale workpieces and everything in-between. Titan's adaptive ecosystem empowers your team to process parts on your own without hard fixturing.

Stationary & Articulated

Agile & Mobile

Rail & Gantry

Multi-Robot

Turn-key adaptive autonomy, for your high-mix problems.

We rapidly configure your robot, process, and interface to keep your operators executing high-value tasks. This is the next evolution in industrial robotics.

-

Sanding & Grinding

Improve consistency and reduce worker strain with sanding that precisely maintains uniform pressure and controlled coverage across all regions of a workpiece.

-

Non-Destructive Inspection

Run dangerous radioactive or tedious surface inspection tasks such as Xray, Surface profiling, Microwave Inspection, TeraHertz inspection and more.

-

Painting

Increase quality and consistency of dynamic paint operations that handle traditional paint process constraints while using the dynamic and flexible autonomy stack that Titan Provides.

-

Drilling

Achieve precise depths and accurate placement all while being flexible to the variability of the real world.

-

Cold Spray

Improve the quality, durability, and consistency of Cold Spray repairs with precise material deposition and optimized adhesion.

-

Blasting

Achieve consistent, quality blasting results while reducing the risk to your workforce.

-

Laser Depaint

Use lasers in place of sanding or blasting to achieve higher quality results with less material waste, and less fatigue to the workpiece.

-

Milling

Open up opportunities for previously difficult or impossible types of milling profiles all while achieving improved consistency.

-

Polishing

Ensure a flawless finish while minimizing worker fatigue with polishing that delivers even pressure and consistent coverage across every section of the workpiece.

Deployments.

Not demos.

Here is a brief collection of our field deployments we’re really proud of.

Trusted by incredible clients, and partners.

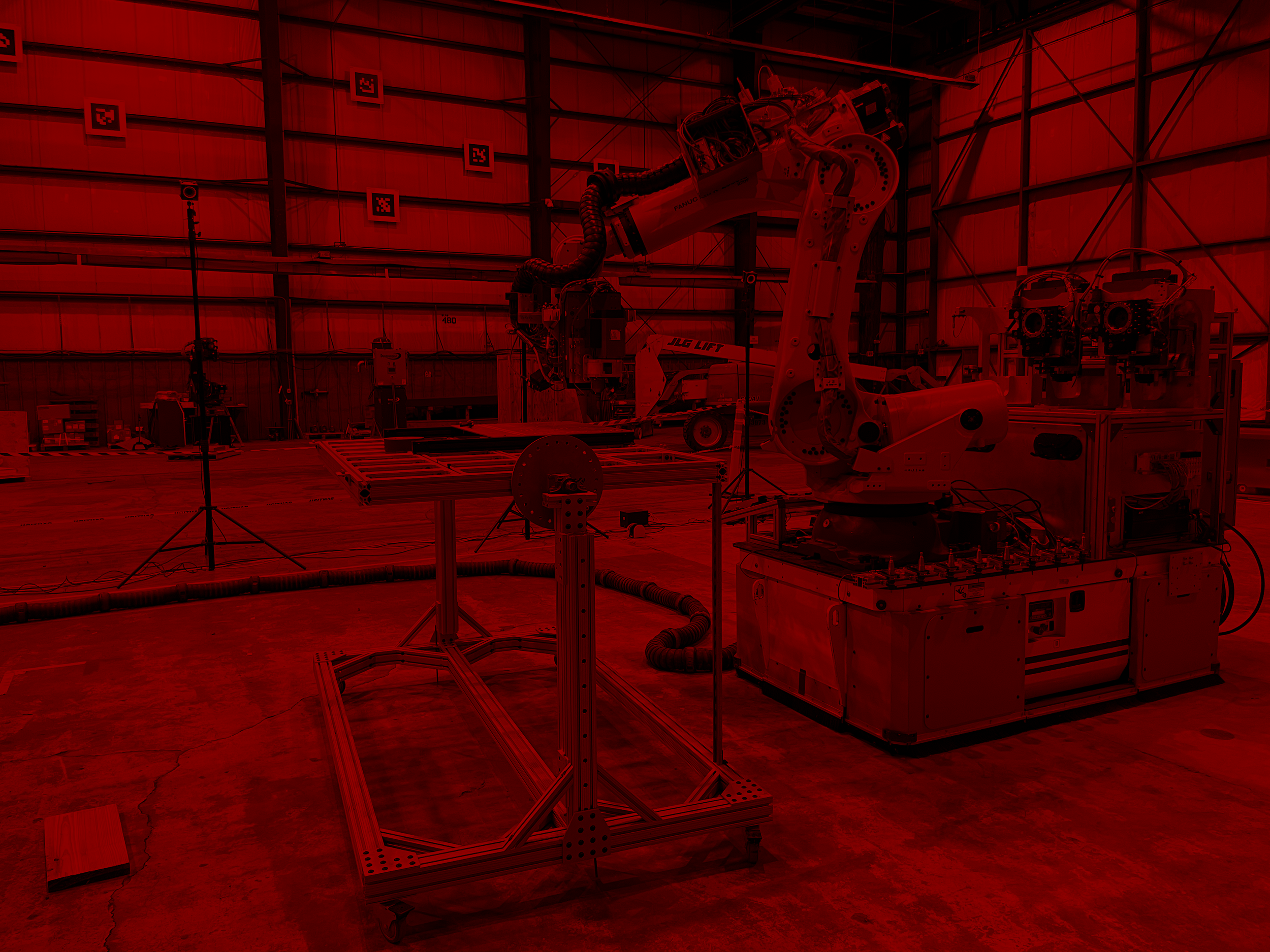

Expanding State of the Art with the U.S. Air Force

Titan Robotics is proud to partner with the U.S. Air Force to modernize aircraft maintenance through advanced, adaptive robotic systems. From laser paint removal and cold spray to our multiprocess radome repair solution and beyond, our technology is redefining efficiency, safety, and precision across mission-critical workflows.

This video highlights our radome repair workcell—an operator-friendly system that streamlines inspection, sanding, and drilling with intuitive touchscreen control and augmented reality guidance.

Watch the video to see our technology in action, and contact us to learn how Titan can support your operations.